ARTICULATED LOW-FLOOR CITY BUS

HIGHLIGHTS & OVERVIEW

IK-218N - Keeping up with the best

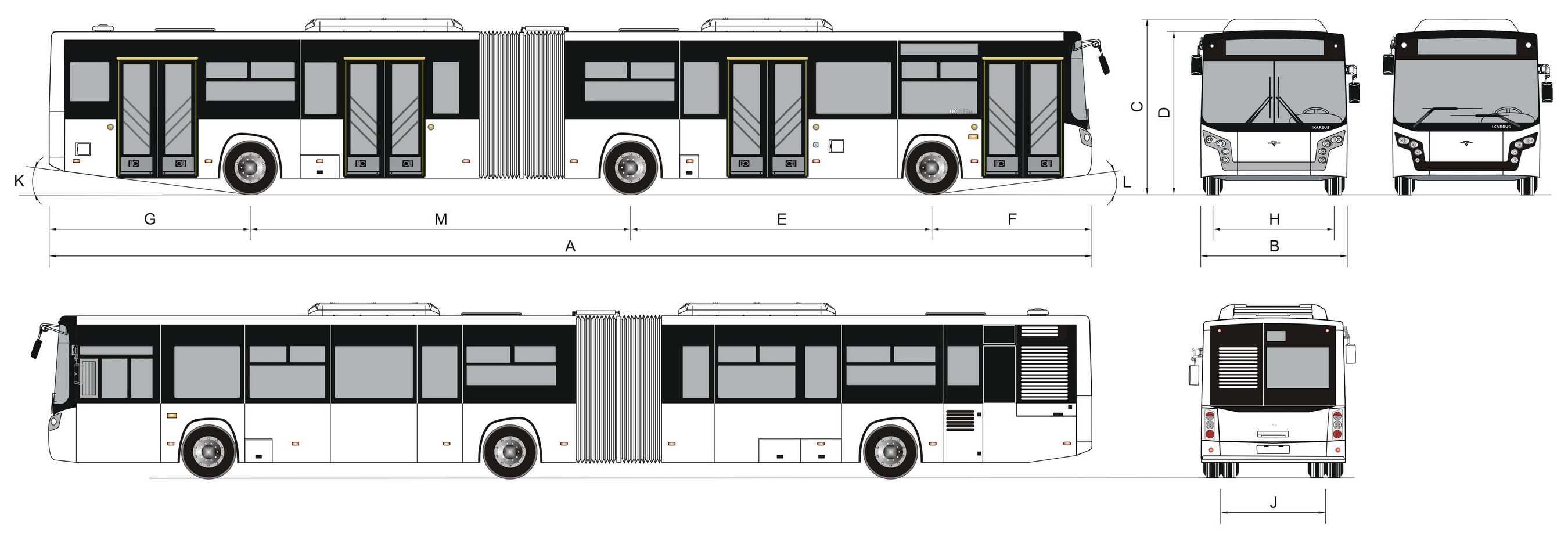

IK-218N is a 18-meter long articulated low-floor urban bus for public transport. This model is constantly being improved for over ten years, and is always up to date with new trends in urban bus production. It is built on our own chassis and complies with EEV norm for exhaust emissions.

Low-floor concept for easier accessibility

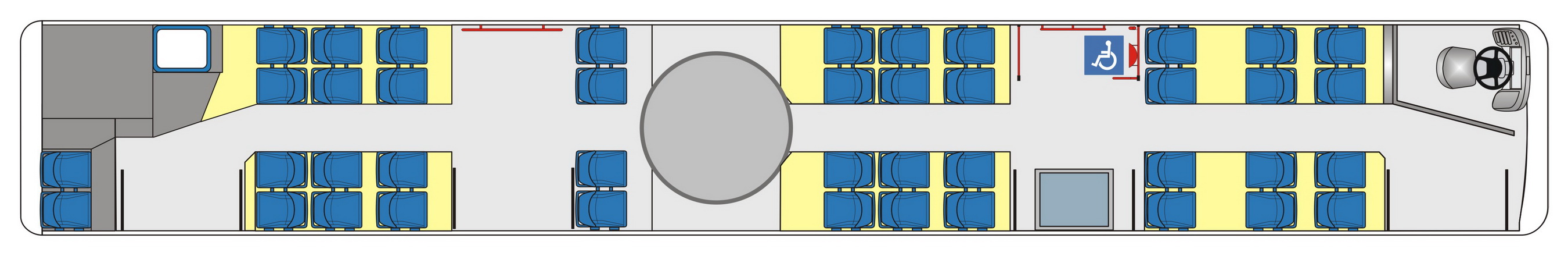

With floor height of 340 mm at the doors and low floor throughout the whole length, this concept is oriented towards passengers. Electronically controlled air suspension system allows the bus to be lowered to ease the access of passengers with reduced mobility. Bus is also equipped with folding ramp for wheelchair users or people with pushchairs and has a special space for their accommodation.

Comfort is priority

Standard configuration includes 40 passenger seats and a total capacity of 160 passengers. Seat inserts can be plastic, with fabric only, or upholstered (light or thick). First row can be fitted with jumbo seats that are intended for passengers with special needs or people with children.

Driver’s workplace complies with ISO 16121 and VDV standard for low-floor buses in public transport. Dashboard and steering wheel angle and height can be adjusted to fit various drivers regardless of height and anatomy. Display integrated in dashboard provides information (for vehicle and system’s status) using standard symbols and textual messages.

Made for all conditions

Heating is provided by radiators and/or blowers (fan heaters), with optional roof heating. For cold starts there is pre-heater with circulating pump that can warm up the system with engine turned off. It can also be used in addition to engine when there is need for more heat (very cold weather).

Air condition and tinted windows are a life saver during summertime. For mild conditions there are sliding windows on both sides and electrically operated roof hatches.

Electronic architecture for total integration of systems

Everything starts at the standardized driver’s workplace which is connected to the central computer that (along with four peripheral computers) controls all other systems (EDC, ECAS, ABS/ASR…). This architecture simplifies the design and maintenance since there are less components and wiring. Bus is equipped with automatic bus stop brake that prevents driving with doors open. Each door has its electronic system that can prevent passengers from jamming. Bus is equipped with articulation angle sensor in order to prevent the turn table from breaking. At higher angles engine output torque is reduced, while the brakes are activated in case of reaching critical angle.

High-end technology for drivetrain

IK-218N is powered by 10,5-liter vertically mounted MAN engine that can deliver 235 kW (320 hp). It is equipped with modern injection system Common-Rail and turbo-charger, which provide greater performance regarding power output, fuel consumption and exhaust emissions. Catalyzer with SCR technology (Selective Catalytic Reduction) is used for exhaust after treatment, and AdBlue reagent is used to reduce NOx emissions so the engine complies with EEV norm. Engine is paired with 4-speed automatic transmission VOITH DIWA.5 with integrated retarder and variable ratio in first gear.

Modern construction for long life

Body structure is made from ferrite steel beams and additionally protected. Glazing and side panels are glued onto the body, and made out of various high-quality materials such as aluminium, stainless steel, polyester, etc. Side panels are made of aluminium sections, while the roof panel is made from one-piece pecolite. Stainless steel is used to cover the gap between windows and roof, while front and rear walls are made out of polyester.